Introduction to manufacturing process:

PI material is injected into the module surface to protect the module from collision and scratches or water and gas intrusion.

Common problem:

The filling of PI material can produce a large number of bubbles in the interior or surface. These bubbles not only affect the appearance of the appearance, but also cause the product reliability

Problem solving application:

When the PI material is filled, the bubble can be eliminate by applying pressure and heating baking to the product in the cavity.

PI Material

Tg : >300c

Test Equipment

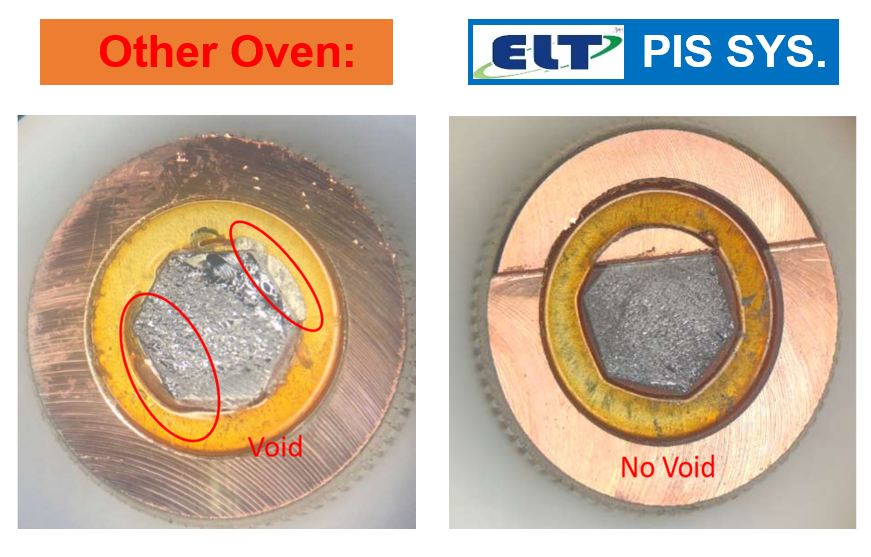

Other Oven & ELT High tempreature vacuum Oven

Test Result:

ELT PI shows no void after pressurized curing.

X-section also shows no void